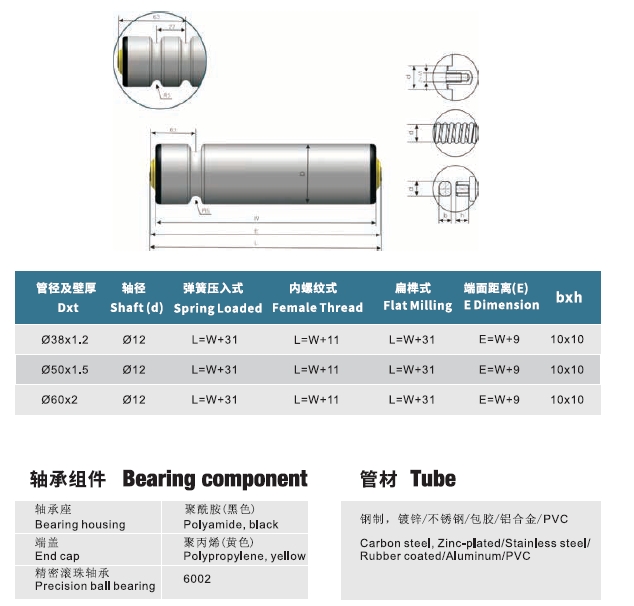

K300 Series

O-ring Conveyor Roller

1.Compared with sproket drive, belt drive has the feature of high speed and low noise,"O-belt" is the most popular way of belt drive.

2.Roller driven by the fliction of the "O-belt" in the groove of roller. To avoid the damage of the static to the goods (eg.CMOS chip in electronic industry), anti-static design isalreay the standard configuration of this product.

3.Except standard type, the position and nubmer of grooves could be cusotmized (not suggest 4 or more grooves onone roller).

4.The load capacity of roller depend on the driving power of"O-belt" and the transmission structure(line shaft drive ishigher than hook-UPS), reference data is normally 300N.

5.Precision ball bearing and inner/outer bushes form the bearing unit which is very important, it is not only for good looking but further more for the roller running moresmoothly and quiet.

6.The covering of the end of roller, well dust proof and water splash proof in operation environment.

7.Suitable for high speed conveying.Speed could varyaccording to diameter and length of roller, Max. Speedreach 120m/min.

8.Operation temperature: -5-+40℃

DOUBLE GROOVES DRIVE: Similar as hook-ups in the double sprocket drive, O-belt fixed in the groove or roller, through O-belt driven, one roller pulling another roller to convey.

1.Easy arrangement, simple installation and maintenance.

2.The torque decays more quickly, normally single roller could pullonly 7-8 passive rollers, the weight of coneyed unit should not exceed 30kg.

3.The length of O-belt loop could be decided as requirement, no muchrequirement for the roller center distance.

4.Preloading value is needed for the length of O-belt loop, it could be different according to the different O-belt manufacturer(detais confimmed with O-belt supplier), normally make preloading value of 6%-8%, that is, reduced by 6%-8% from the theoretical length of loop.

SINGLE GROOVE DRIVE: Conveyor driven by the drive shaft(popularly named line shaft) under the rollers, line shaft installed with driving wheels, O-belt turn around 90 degree and fixed in the roller groove and driving wheel. Roller driven by the running of line shaft, refer to chart below:

1.Every roller's driving force is transmitted by the line shaft separately, compared with double grooves drive, it has more load capacity, mainly applied in the long distance convey, the Max. convey distance could reach more than 10 meters.

2.Could realize the curue coney(line shaft could be connected by universal joint coupling).

3.The maintenance(change O-belt)is relatively difficult, need to disassemble the whole line shaft.

Annika Johansson 2019-01-04

A great partner for our company! If you hear about YGC and start to cooperate with them, you will get unexpected surprise from them. Due to their professional ability, we can import conveyor rollers smoothly and nothing to worry about.

David Miller 2019-01-04

If you are looking for a conveyor system provider, please choose this company as their technical skills are very strong. Whether whole system or just conveyor component, they will show you the best, of course you will get the best also. With this guarantee from them, you can choose all kinds of conveyor products from them if you have the needs.